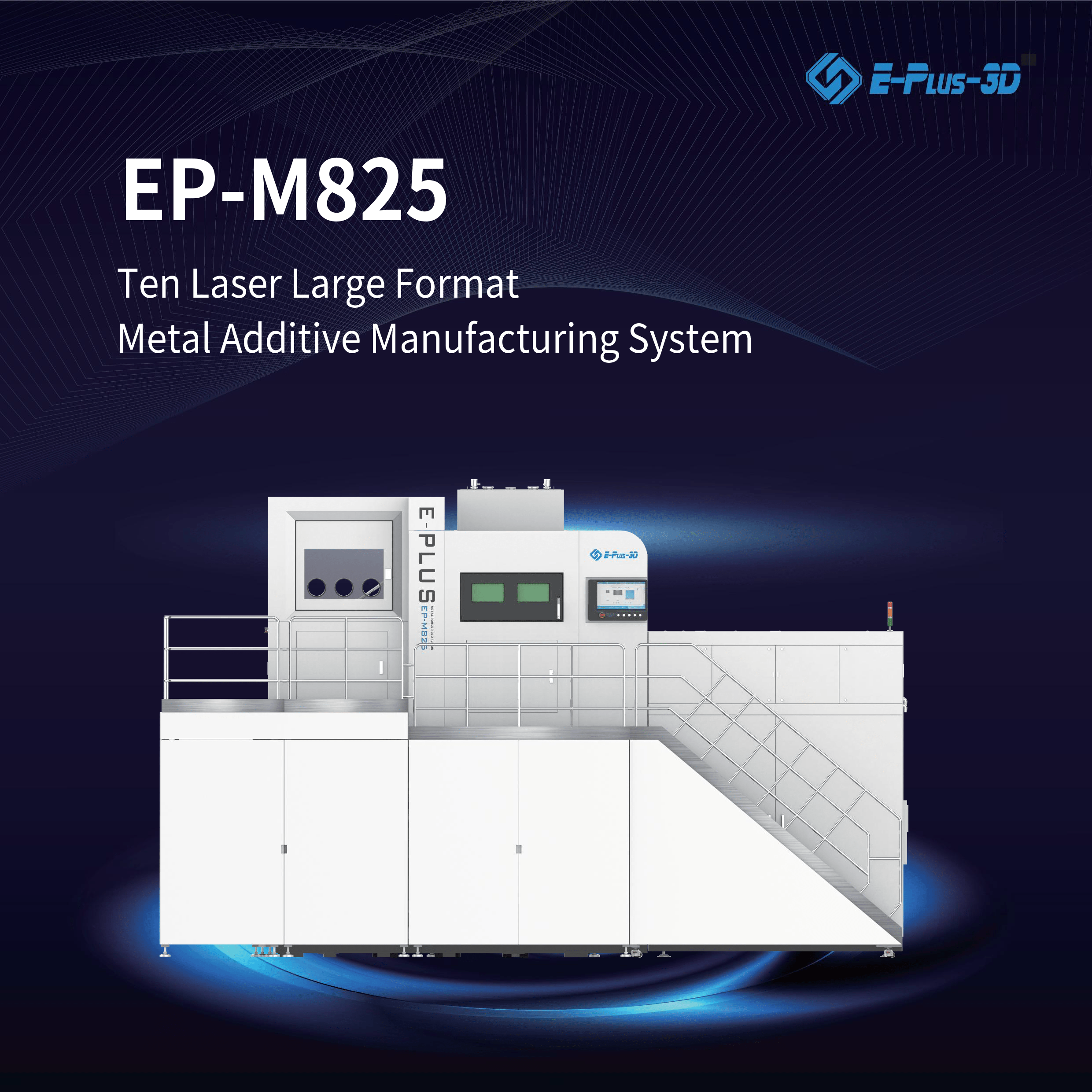

EP-M825 Metal 3D Printer

The EP-M825 Metal 3D Printer from Eplus3D is designed for high-efficiency production with a large build volume and a ten-laser system. It is perfect for manufacturing high-performance components for industries such as aerospace, automotive, and mould manufacturing.

High Efficiency & Productivity

Ten lasers printing simultaneously with speeds up to 410 cm³/h.

Excellent Quality & Consistency

Accuracy deviation of lap area less than ±0.1 mm with consistent mechanical properties.

High Precision

High-quality laser beam with precise positioning control.

Easy Operation & Maintenance

User-friendly interface and fully automatic functions.

Real-Time Monitoring & Security

Safety design to prevent misoperation, fire, and other risks.

What can EP-M825 print?

- Rocket Engine Nozzle Expansion Section — Stainless steel, 1050 x 160 mm, Aerospace.

- Rocket Compartment — In718, 630 x 630 x 1100 mm, Aerospace.

Technical Specifications

| Machine Model | EP-M825 |

|---|---|

| Build Volume (X x Y x Z) | 825 x 825 x 1100 mm |

| Optical System | Fiber Laser 4 / 6 / 8 / 10 x 500 W |

| Spot Size | 70 – 120 μm |

| Max Scan Speed | 8 m/s |

| Layer Thickness | 20 – 120 μm |

| Theoretical Print Speed | Up to 410 cm³/h |

| Material | Titanium Alloy, Aluminum Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome |

| Power Supply | 380 V, 50 / 60 Hz, 29.5 – 40 kW |

| Gas Supply | Ar / N2 |

| Oxygen Content | ≤ 100 ppm |

| Dimension (W x D x H) | 8290 x 4690 x 5470 mm |

| Weight | 35000 kg |

| Software | EPControl, EPHatch |

| Input Data Format | STL or other Convertible File |

For detailed technical specifications, download the PDF datasheet:

Ready to transform your production?

The EP-M825 Metal 3D Printer from Eplus3D is designed for high-efficiency production with a large build volume and a ten-laser system. It is perfect for manufacturing high-performance components for industries such as aerospace, automotive, and mould manufacturing.